This is a project that just about anyone can do and get amazing professional results! We will be making the crown jewel of our grill island project, the polished concrete countertop.

You can use the following procedure to make countertops for many other applications.

We start similarly to the way our grill island (link to Build The Ultimate Outdoor Kitchen Grill Island article) began. Not with digging, but with a form.

Measure your island and be sure of the dimensions before you start. Because of the irregular shape of the field stones on the sides we added a 2 inch overhang on all sides. This time instead of using 2 x 4’s for forms we are going to use melamine.

Because of its smooth finish, melamine is much easier to remove once our concrete has cured. The texture leaves the cured concrete countertop with a relatively smooth surface.

Cut the piece for the top of the countertop 1.5 inches wider, to accommodate for the installation of the side pieces. Cut strips for side pieces as thick as you want your countertop (ours were 2 inches).

Make your countertop as thick as you would like. It must be thick enough so that it won’t crack. For our project if felt 2 inches was a safe thickness. Bear in mind that the thicker it is, the heavier it will be.

Clamp the side pieces in place one at a time and pre-drill and countersink the screws. If you don’t countersink the screws, they will be in your way when it comes time to level the concrete.

Keep It Clean

Once your form is all screwed together, remove any dirt or sawdust that is on the surface. This can be done with a lint free rag and rubbing alcohol. Compressed air also works well to remove sawdust, be sure to wipe it down before you go to the next step.

Using silicone, place a small bead ¼ inch or so, on all the seams and smooth them out with your finger. Be sure there is no excess, as that will leave a void in your finished top.

Again, be sure the surface is clean and let the silicone set up for 24 hours before the next step.

More Choices

Your countertop can be completed in two ways. The first is to make an unpolished top:

steps for an unpolished top

- pour concret

- let it cure

- remove form

- flip over

- seal

- enjoy your new countertop

If this is the route you choose then you can skip down to the next section.

The other option follows the same procedure with one added step before it gets sealed. The countertop gets polished.

If you plan on polishing your project, it allows you to place objects and designs into your top! Now is the time to unleash your creative side! After all you are building a concrete countertop from scratch, why not put your unique “stamp” on it.

Our project needs two forms. One for the main countertop for food and grill prep, and one for the elevated bar area.

For the bar area we placed broken glass and a “K” made from pieces of granite representing my last name. This is just an example of what's possible. Be creative, you can place just about anything in your countertop.

That Personal Touch

To create the “K” I took one of the rocks and sliced it into 1⁄2 inch thick pieces on my wet saw. Then I cut the slices into strips to form the letter.

I drew a circle on my form, and used white glue and covered the circle. Returning to my childhood here, I was thinking it would work the same way glitter worked on projects from preschool.

I placed my pieces of cut stone and pressed them into the center to form the letter. Then I took the broken red glass and sprinkled it all around within the circle. Allow the whole thing to dry overnight.

Not sure if regular white glue is the best thing to use to hold it all in place, but it worked OK for me. On my next project I will try using rubber cement or something a little more durable than white school glue.

Mix It Up

It’s time to get our hands dirty again. My choice in concrete was a high early strength concrete.

There are several types of concrete countertop mix (link to Amazon for price and availability) on the market. The one we chose was fortified with fiberglass to help reduce cracking. To determine how much concrete you will need, refer to the manufacturer guidelines.

Mix the concrete thoroughly into a peanut butter like consistency. Shovel, or bucket it into your form. I started in the corners first, and made sure to pack it tightly. Rubber gloves are a must for this. The concrete will chemically burn your skin.

If you are going to put a design on your top, be sure not to disturb it too much when you place the concrete on top of it. It works OK if you pack it straight down, but try not to move it side to side.

Fill the form completely, then use a straight 2 x 4, or other straight edge to pull toward you in a sawing motion and level off the top (really the bottom). The same way it was done when building the foundation.

Time For a Shakedown

To remove any voids and air pockets the whole thing needs to be vibrated. This allows any air trapped in the concrete to rise to the surface.

Your countertop is upside down, so any air trapped at the bottom will leave a void in the top. I’ve watched people use a rubber mallet to accomplish this, but it seemed like a lot of work, especially on a large countertop.

My solution was to use my reciprocating saw (link to Amazon) without a blade on it. I held it directly under the form, and on the sides, and vibrated it like crazy.

It’s amazing how much air gets trapped in the concrete during the mixing and pouring process. Do this until minimal air bubbles rise to the surface… yes, it takes a while.

Don’t Rush The Cure

When curing concrete, don’t let it cure too quickly. I kept my countertop covered with plastic for a week, spraying it with a hose daily to keep it moist. This helps to slow down the curing process. This will reduce the chance of cracking.

I poured my concrete into the form that I had resting right on the grill island. It took approximately 4 and ½, 80 lb bags for a total weighing 360 lbs. That’s 163.3 kilograms for my friends outside the United States. This thing is too heavy for one man to move!

After it was cured for a minimum of one L O N G week it was time to remove the form and reveal my creation. Take care in removing the form.

The concrete can still chip off the edges. Use a pry-bar against a piece of wood for the stubborn pieces, never use a pry-bar directly on the concrete.

Gather Your Friends

This next part took some creative engineering. We needed to flip this monster over, then place it exactly where it would rest. This is where we go back to that famous nation… DETERMI-NATION.

There were 5 people to help move this beast! Use leverage and not your back. The top was maneuvered onto a few 2 x 4’s and my picnic table. We then slid the top, with the form still under it and the sides removed onto the 2 x 4’s.

With the counter off the island I mixed up a batch of mortar and placed a bed all around the perimeter of the grill island. Then using all our might, we flipped the monstrosity over.

Slowly and carefully we put it in position and laid it to rest. If you do this remember, communication is key when working with other people. The whole process is no way to lose a finger, or worse, just be careful!

Going Through The Motions Again

I repeated this step again for the upper countertop. The one with the broken glass in it. Being much smaller and lighter, it was easier to maneuver, and required fewer of my tired friends.

While building the grill island itself I installed conduit (plastic pvc pipe that houses electrical wire) through it. When I poured the concrete for this countertop, I placed a piece of conduit on one side.

The conduit is there to run wire for lamp post of some kind in the future. Consider these things as you go, so you can set yourself up in the future.

If you want to stop at this point and enjoy the fruits of your labor, by all means do just that! Enjoy your new concrete countertops. If all you were after was a solid place to slice, dice, and roll out your pizza dough, mission accomplished!

Seal the concrete and enjoy. BUT... If you MUST go that one step further keep reading as we finish this top off properly!

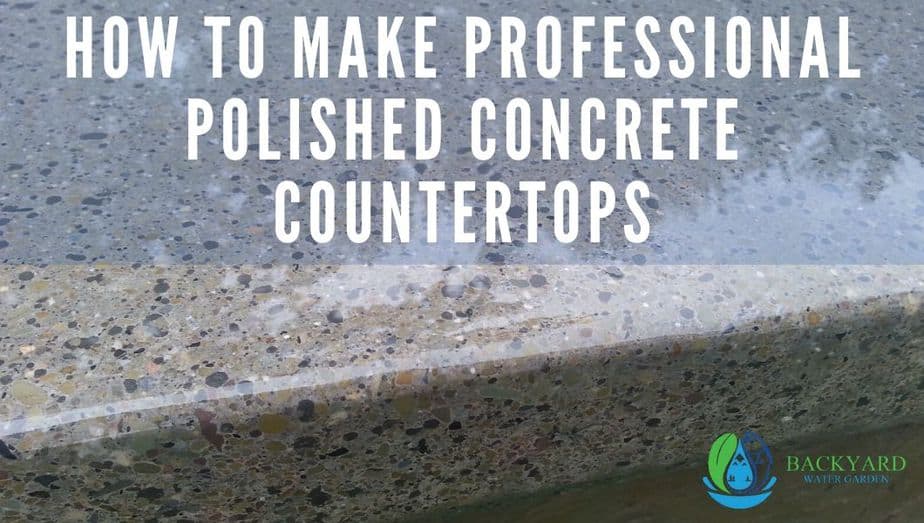

Polishing Concrete Countertops

Polishing your concrete countertop will bring the wow factor to your once plain cinder block grill island. Get professional looking results step by step.

Right now you have a raw slab of concrete resting on your beautiful stone or tile work. This process, will make your concrete look worse before it looks better. It’s worth it… trust me.

You will need a concrete polisher (link to Amazon for the one I used), before you can get started. Here are the materials you will need:

Material List

- Fine grout

- Portland Cement

- Acrylic bonder

- Concrete sealer

Required tools

- Concrete polisher

- Drywall knife

- Safety glasses

- Rubber gloves

- Rain gear

DIY Concrete Polishing

Hand held concrete polishers all work about the same. Look for one that has variable speed so you can adjust it to fit the finish you are trying to achieve.

I found this concrete polisher (link to our review of this polisher). It comes with the polishing disks you will need.

Some polishing disk sets, come with more grits than others. The discs are numbered. The lower the number, the more coarse and more aggressive the grit is.

These disk sets are fairly cheap. If you already have a polisher and not a diamond disc set (link to Amazon) you will need one before you begin.

This is what the upper bar countertop looked like right out of the form. It looks bad before you get at it with the polisher.

Before

After

Start with the coarsest grit, it may be 30 or 60, and start removing the surface layer of the concrete. Be sure to keep it flat, holding it at an angle will create an uneven surface, especially with such an aggressive grit. Do this over the entire area. When you’re done, it will look worse than when you started. You can see the difference in the picture below between polished and unpolished.

Add That Personal Touch

This is a great time to add an edge to your top with the aggressive grit. It will remove material very quickly. You can add a bevel or a round over. Play around with it. This is one of those skills you get better at the more you do. I put a bevel on the upper top and a round-over on the lower.

When you are finished you will notice holes and crevices all throughout your top. Don’t freak out, this is perfectly normal. I know you thought you got all the air bubbles out, guess again!

Mix up a dry mix of 1 part Portland cement, and 1-part fine grout (I used fine grout because I had some left over from another project). This will make a slurry.

The color of your grout will affect the color of your slurry. I used black grout so it would blend in and be subtle. Instead of using water, use latex bonder (link to Amazon). The bonder helps the slurry stay put in the tiny spaces.

Pour the slurry on your countertop. Use an 8-inch drywall knife to spread it around and push it into all the voids. Allow it to dry for 20 minutes or so, then use the knife to scrape off all the excess. Let it set up overnight.

Using 100 grit on your polisher, remove all the slurry. Depending how much your slurry shrunk, you may need to repeat the above process. Once you are happy with the top and all the voids are filled move to the next step.

Get Out Your Rain Gear

This takes time and some getting used to. You WILL get soaked. Now that you’ve got the whole thing polished to 100 grit it’s time to put in the elbow grease and make it shine.

Go over the entire top, and sides with each grit. Be sure to rinse off the top between grits to get rid of any excess material. Let the polisher do the work. No need to press down hard. If you do, you may create a low spot, especially with the more aggressive grits.

It will look more and more beautiful with every grit. When you’re finished you won’t believe that it was only ordinary concrete.

I Can See The Finish

Allow the top to dry completely before adding sealer to it. There are countess options for this as well. I just chose a high gloss sealer to bring out the colors in the concrete.

If you are going to acid stain your top, now is the time to do it. I don’t have experience with acid stain, but I have seen the amazing results you can achieve with it.

If you plan on experimenting, I suggest this acid stain sample kit (amazon link). After all that hard work, it’s a good idea to “try it before you buy it”.

As you can see below, sealing the concrete really brings out its natural color.

Before

After

The sealer I used required the concrete be at a certain temperature, and not in direct sunlight for proper curing. I sealed it later in the evening when the summer sun went down.

Be sure to follow the manufacturer's instructions for best results. I applied the sealer with a 4” foam roller. This type of roller had 0 nap, to leave an ultra smooth finish.

Before the Action… Lights

Don’t bust out your grilling skills just yet. There is one more thing to add before our job is complete. We need lights to set this thing off!

To get full use of our island and enjoy the nightlife we need to add some lighting. I ran conduit when I was building my slab so when I got to this point everything would be easier.

I placed a GFCI receptacle inside the island so it would be out of the weather. I still put it in a waterproof electrical box though.

I used these LED light strips (link to Amazon) that operate on a remote control. They are awesome, use very little electricity and the color can be changed to fit the mood.

These lights are encased in silicone and are flexible. I attached them to the underside lip of the counter using clear silicone. Use tape every foot or so to hold the lights in place until the silicone sets up.

After a couple hours remove the tape and go over the whole thing with more clear silicone. This will not only hold everything in place, but it will seal the lights and completely keep them out of the weather.

Conclusion

In our next post we will be adding the final touch to this project, adding a lamp post to our bar.

Now you know how to build the ultimate outdoor kitchen grill island complete with polished concrete countertops. Time to fire up the grill (link to our grill review article) and let your grill master skills come in to full play!

You may start to make some new friends. The tempting aroma of delicious grilled food will be sure to draw in the neighbors.

All the hard work finally payed off, creating an amazing outdoor space that will last for years with little to no maintenance. Take some time and enjoy this before moving on to the next project (link to other outdoor projects)!

~Jeff

This is AWESOME! We have an unused BBQ area at our home and I want to repurpose the area into an outside kitchen. The concrete countertop would suit perfectly and be a real feature… I’m sure we’ll get so much more use out of the space. Thank you so much for sharing, Cheers, Karen http://writingforcash.com

Hi Karen, how soon until you start. If and when you do, be sure to plan it out well and that you make a solid foundation. Best of luck on your future project. If you have any questions feel free to ask. Thanks for visiting.

Hi there

So my dad is pretty handy himself, and actually read this with me. was really impressed with it. I had no idea all the work thats involved with a project like this. Me myself I dont know if I could handle it, but I suppose with his help I could manage. Thanks for the post.

Yes, something like this doesn’t happen overnight. I believe anyone could accomplish this with the right guidance and patience. Thanks for checking it out.

This is amazing Jeff =) Thank you for the guidance. I am on a lookout for this and you gave a good presentation. I’ll definitely try this out. Aesthetically nice =) Thanks bro =)

Thanks for visiting. Check back if you ever start a project like this!

Very nice! Did the design sit well while pouring the concrete or did you have to re-adjust the “K” design after the concrete, before it set?

Thank you. Actually i had no idea if it had moved or not. Once the concrete is poured you just have to hope for the best and see how it comes out. Fortunately for me it worked out OK. I will have pictures of it in my next post.

I never thought about polishing concrete. What a great idea. It looks like your counter tops turned out beautifully. I love the lights you added!

I came across the idea looking for a different way to keep a counter-top that can stand up to the winters we have. This was the perfect solution. Easy to clean and very low maintenance.The same can be applied to finish concrete floors as well.

This was a very interesting series of articles you put together. I must say that I would love to have the finished project right outside my door but it doesn’t look mobile to me without a crane, lol. I think you did a beautiful job on your masterpiece and your instructions are easy to follow as long as you know some basics. Great job.

Once something like this is in place, it’s not going any where. It will probably last longer than my house! If you have any questions, feel free to ask. Thanks for visiting.

Interesting article I never thought about polishing concrete counter tops.

I don’t have any myself but my brother does, so I will forward your post to him.

I am wondering if this would make a good business to start? How long does the whole process take from start to finish in order to get the counters polished?

Great question Chris, it took me about 6 hours total over a couple of days. The polisher I used wasn’t the greatest so I imagine if you were going to turn this into a business you would want better equipment. It’s amazing what is beneath the surface once you start grinding and polishing. If you have any other questions please don’t hesitate to ask.

That outdoor countertop is fantastic! What a beautiful piece for your backyard. How long have you been able to use it? Have you seen any wear and tear on the polish?

Thank you. There as been no wear and tear on the finish of the concrete. However the sealer does need to be added every year to keep it looking its best. Its seen 2 winters so far and it still looks like the day I finished it. Great question, if you think of anything else please don’t hesitate to ask.

Wow, what beautiful counter tops. The polish look looks like granite. This seems like a great option for outdoors particularly because of the no maintenance. Is this a one man job and can a novice really accomplish this in your opinion? It sounds like it but everything seems easier until you take on the actual project 🙂

Thanks for the compliment. Yes anyone can achieve this, and yes it is perfect for the outdoors. Especially in a climate where there is winter. If you follow the steps in the article you will be successful. The only part you would need an extra set of hands is when it comes time to move the countertop from the form to its final resting place. That’s where you will need some extra help. The materials are relatively inexpensive, start small and give it a shot. You never know unless you try. If you have any other questions, be sure to stop back and ask. I will be happy to help. Good luck to you on all your future projects!

The countertop looks so nice. Such a great idea for outside use… easy to clean and looks like it would hold up really well.

It has held up great so far. My wife loves it because when we are done using it, she grabs the garden hose and hoses the whole thing off. Very low maintenance.

Your post is fantastic, Jeff. I was searching for some valuable information regarding polished concrete countertops and found it here. You covered almost everything in your post. Keep up the excellent work. Cheers!

Which sealer did you go with? There are so many options on the market and they all seem to have their own drawbacks. Have you been ultimately pleased with how your sealer held up and the level of maintenance that was required?

Marty,

The sealer I used is a polyurethane sealer from direct colors. Here is a link

https://directcolors.com/polyurethane-sealer/

I have tried others, and none seem to bring out the color of the concrete like this one did. It has held up to the elements over the years even through harsh winters. It needs to be reapplied every 3 years or so.

Use a foam roller and keep a wet edge and you will get professional results. This worked very well with no maintenance issues. Be sure you are in a well ventilated area when applying, because the smell is a bit overwhelming. Would love to see pictures of your finished project!

Cheers,

~Jeff

Hi Jeff, Your BBQ island looks great! Thanks for sharing. Can you say what aggregate you used in the main concrete mix?

Thank you.

Bill

Thank you, these countertops have stood up great even through harsh winters. The aggregate used was Quikrete crack resistant concrete mix. I used this because it is fiber reinforced to prevent cracking. I wanted to take every precaution, since the countertop was only around 2 inches thick.

I just love all of your unique and awesome tips. I learned a lot of new and innovative ways of maintaining our polished concrete floors. I am looking forward to reading more posts from you. I admire your expertise. You are an inspiration.

Thank you for the positive feedback. Glad I could help.

Cheers,

~Jeff

hi Jeff,

Can you send me a link to the sealer and the brish you used?

the company built me a polished concrete bar top but left without a seal and I love your finish.

Its outside but under a pavillion. I am in Maryland & its summer (80s).

TY

Jenny

I got my sealer from https://directcolors.com they have a great variety of staines and sealers. I went with a high gloss and applied it with a foam roller. Good luck with your project!

Cheers!